FunGlass

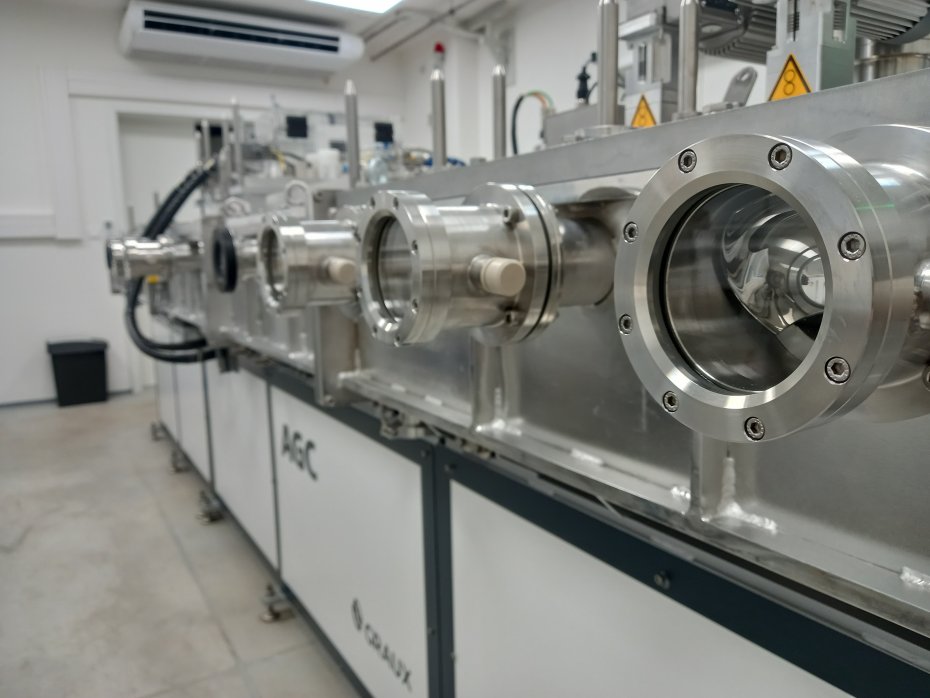

Installation of a lab-scale vacuum coating line including PECVD and PVD modules.

Partner with leading academics in glass science to develop next generation thin-film products.

About project

The Centre for Functional and Surface Functionalized Glass (FUNGLASS) is a center of excellence operating under the framework of Horizon 2020. It is led by Prof. Dušan Galusek at Alexander Dubček University of Trenčín in Slovakia. The primary objective of FUNGLASS is to establish an internationally renowned research center focused on glass-based functional materials.

FUNGLASS collaborates with several leading experts in the field of glass science and technology from esteemed institutions across Europe. These partners include:

- Friedrich-Alexander University Erlangen-Nürnberg (Germany), represented by Prof. Aldo R. Boccaccini.

- Friedrich Schiller University Jena (Germany), represented by Prof. Lothar Wondraczek.

- Spanish National Research Council (Spain), represented by Prof. Alicia Durán.

- University of Padova (Italy), represented by Prof. Enrico Bernardo.

By leveraging the expertise and resources of these partner institutions, FUNGLASS aims to conduct cutting-edge research in the field of functional materials derived from glass. The center strives to generate significant contributions to both scientific knowledge and practical applications in this area.

Client situation

FUNGLASS is actively engaged in both academic and industry-related projects. It aims to attract talented researchers from around the world, providing opportunities for them to pursue their PhD studies or work on postdoctoral projects within the center.

One of the research areas FUNGLASS is focusing on involves surface functionalization using coating technologies. This includes developing anti-reflection coatings for solar energy production, enhancing the corrosion and leaching resistance of commercially produced glasses, and applying self-cleaning, antibacterial, and photocatalytic coatings to glass for various applications.

The suggestion of solution

The PlasmaMAX™ technology developed by AGC Plasma is a PECVD (Plasma Enhanced Chemical Vapor Deposition) tool that offers a versatile platform for coating deposition. The ultra-high rate PlasmaMAX™ tool allows for the utilization of different precursor chemistries, providing researchers with the flexibility to obtain a wide range of coatings with varying properties and functionalities. This versatility enables exploration and experimentation to discover new possibilities and applications for coated materials.

Results

AGC Plasma engineered, manufactured, and installed a lab-scale coater for glass sheets with maximum dimensions of 40 cm x 40 cm. The pilot includes 2 modules, with one dedicated to PECVD, and the other featuring both planar and rotatable magnetron sputtering sources. The system allow for the deposition of a range of thin films, including metals, oxides, nitrides, carbides, and even polymers.

Furthermore, the tool's ability to perform dynamic depositions in a laboratory setting makes the upscaling of the technology toward industrial-scale operations more straightforward. This means that the transition from lab-scale research to large-scale production can be achieved with relative ease.

What have we achieved?

The combination of the PlasmaMAX™ technology with magnetron sputtering sources in a single system enables multilayer stack depositions. The integration of these two technologies enables the creation of complex coatings with multiple layers, each having different properties and functionalities.

- A lab-scale coater for coating glass sheets delivered in Trencin, Slovakia

- Develop innovative coating processes by using various precursor materials in combination with the PlasmaMAX™ PECVD technology

- Feasibility to deposit multilayer thin film coatings

- Engagement with AGC Glass Europe for industry partnership and new product development

How does the client evaluate our solution?

The lab coater provided by AGC Plasma is a valuable addition to the infrastructure of FUNGLASS. It offers state-of-the-art coating technology that enables the center to provide hands-on training to students, allowing them to gain practical experience with cutting-edge equipment and techniques in the field of coating. The collaboration between FUNGLASS and AGC Plasma opens up exciting possibilities for the development of innovative products and the advancement of coating technology.