Astronomical Mirrors

Next-generation astronomical telescopes are designed to expand the boundaries of astrophysical science by enabling new insights into exoplanets, supermassive black holes, dark matter, and even the earliest moments of the Universe.

While essential observation continues to be performed from outer space, an emerging class of extremely large ground-based telescopes is revolutionizing modern astronomy.

Observatories located on the ground allow scientists to more easily maintain and service equipment, which enables the design of increasingly larger telescopes with primary mirror diameters up to 40 meters.

AGC Plasma Technology Solutions is well-experienced in the field of PVD equipment design and astronomical mirror coating technology . With over four decades of industrial experience, our engineers and scientists are well-equipped to oversee all aspects of the design, construction, transport, assembly, and commissioning of a complete PVD coating system. This level of expertise and attention to detail is essential for producing high-quality optical coatings that meet the exacting requirements of astronomical applications. AGC Plasma Technology Solutions is a reliable and reputable provider of these specialized services.

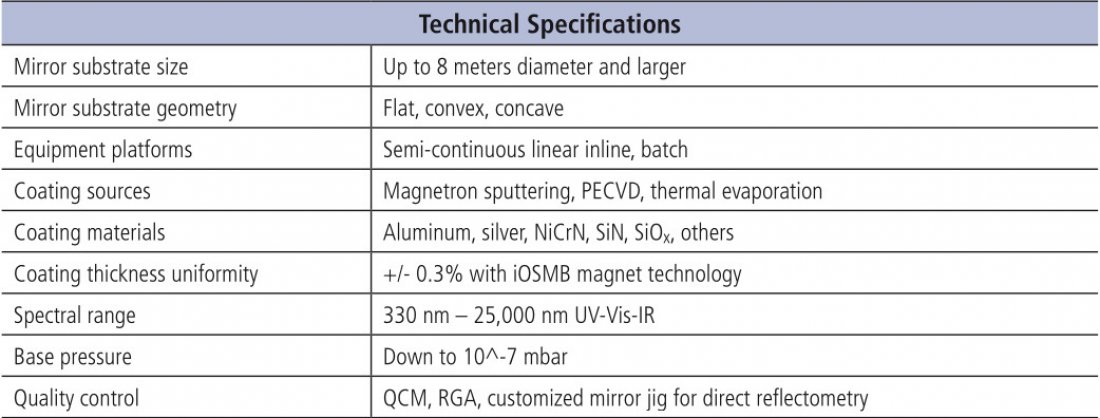

AGC Plasma Technology Solutions understands well the importance of customized coater designs to meet the unique requirements of different telescope systems. By offering both batch and linear inline coating systems, we provide flexible solutions that are both technically reliable and operationally efficient. This ensures that mirror segments of varying sizes and geometries can be coated effectively and efficiently, without compromising on quality. Straightforward upgradeability of AGC coater systems allows telescope programs to easily adapt their coater system for new astronomical science targets.

Many observatories are located at high altitude to secure optimal viewing conditions with favorable weather and minimal light pollution from nearby cities. Such areas tend to encounter seismic activity which, if occurs during a coating process, risks damaging extremely valuable ceramic substrates. AGC astronomical mirror coaters are engineered with advanced stabilization mechanisms and safety features to withstand even the most aggressive earthquakes and ensure the safety of the ceramic mirror.

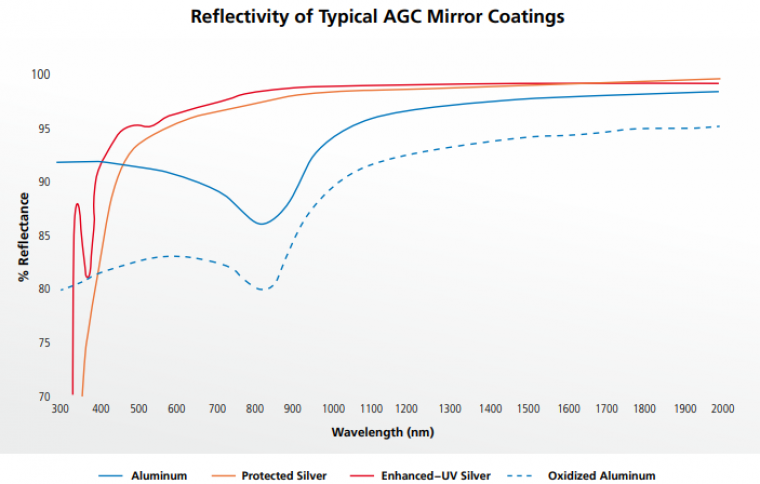

Astronomical mirrors are critical components of telescopes and observatories, and the quality of the thin-film coating on the front surface of the ceramic mirror substrate is crucial to their performance. The choice of coating material and layer stack will depend on the spectral range of light that needs to be reflected and the environmental durability requirements of the mirror. As mirrors become larger and more complex, the engineering challenges associated with producing high-quality and uniform thin-film coatings become more significant. The process requires a high level of precision and attention to detail, as any imperfections in the coating can impact the accuracy and resolution of the telescope system. AGC's experience and expertise in this area make us well-equipped to address these challenges and produce high-quality mirror coatings that meet the demanding requirements of astronomical applications.

Features

- Flexible equipment platform designs allow for wide range of mirror substrate geometries and sizes up to 8 meters diameter

- Precise nanoscale coating thickness uniformity control across large area and 3-D surfaces

- Coating stack design support of world’s leading large area optical coating manufacturers

- Earthquake-resistant design ensures safety of mirror substrate during seismic activity