Green Frix

Development of an industrial plasma reactor for crosslinking of natural derivatives. Upscale from lab-scale to industrial need.

About project

Green Frix, an expert in the cross-linking of oils and their rheological properties, and AGC Plasma collaborated to upscale a plasma process for the treatment of natural oils and derivatives. This process, developed with the Materia Nova research center on a laboratory scale, made it possible to transform the rheological properties of oils at a rate of a few kilograms per day. The development of this process was the subject of a first international patent filed by Green Frix.

Client situation

Green Frix is modifying various natural derivatives such as vegetable oils, esters, and waxes based on soja, sunflower, and rapeseed to bring additional benefits such as:

- Low friction and synergetic effect with anti-wear to prevent surface damage

- Non-Newtonian behaviors such as shear-thinning and thixotropy

- Tailor-made melting point

The novelty of the process developed by Green Frix is that it can be installed locally to treat any type of product in liquid state, whether it is to cross-link a variety of vegetable oils, or to apply the treatment to waste water or liquefied plastic waste.

The suggestion of solution

The initial development of the Green Frix process involved lab-scale equipment and testing conducted at Materia Nova. This phase focused on proof of concept and understanding the fundamental aspects of the process. After achieving promising results at the lab scale, the Green Frix process was further upscaled by AGC Plasma Technology Solutions with the realization of an industrial machine, enabling large-scale manufacturing and commercialization of the Green Frix process.

Results

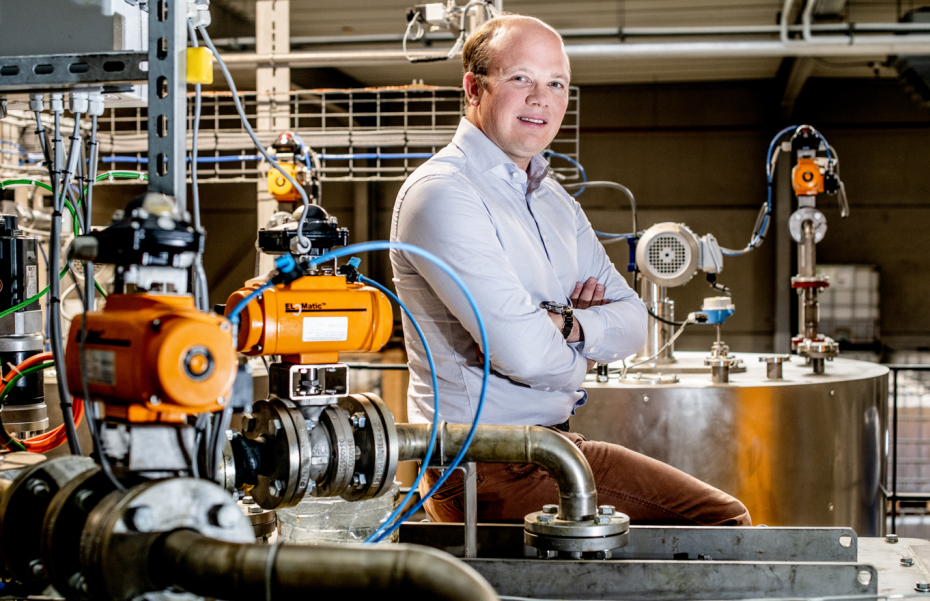

The collaboration between Green Frix and AGC Plasma has made it possible to define the technical specifications, to manufacture and to start production of a unit for the treatment of bio-sourced materials installed in Ghislenghien, Belgium. This production unit allows Green Frix to serve an international clientele in search of innovative and high-performing biosourced materials. After this first fruitful collaboration, Green Frix and AGC Plasma have further strengthened their exclusive relationship by publishing a joint patent and signing a commercial agreement to accelerate the deployment of the technology developed by Green Frix in various fields of application.

What have we achieved?

The association of two industrial partners and a research center has enabled the industrialization of an innovative process for bio-sourced oils and now allows to today offer this plasma treatment of liquids to other industrial sectors.

- Industrial reactor for the treatment of bio-sourced materials installed in Ghislenghien, Belgium

- Explore potential alternative applications for an innovative plasma technology

- Generate joint Intellectual Property rights

How does the client evaluate our solution?

AGC Plasma has been instrumental in the upscaling of the pilot line made by Materia Nova. Their know-how and industrial experience has been leveraged for the realization of the first of its kind production line for crosslinking liquid state products