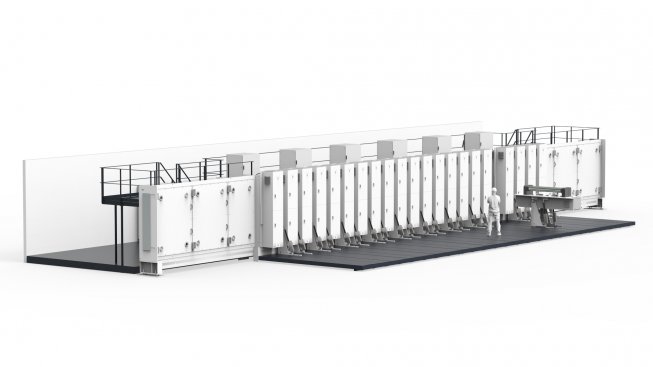

High-throughput mass production line with advanced automation and process control

A high-throughput mass production line with lowest total cost of ownership is realized with the linear inline system. Substrates are loaded onto holders which move alongside carriers through the coater. Loading and unloading of substrates onto holders is automated or can be performed manually. The line can be delivered with a fully automated carrier return system.

Features

- High-throughput coating line relies on AGC’s industry-proven PVD and PECVD technology with superior process stability and reproducibility

- Highest-quality coatings with low particle pollution

- Coating uniformity unmatched in industry with AGC iOSMB magnet bar technology

- Custom-engineered sample holders to optimize line coverage and maximize machine output

- Automated carrier return system operated in a clean space to avoid dust contamination

- Modular and flexible equipment design enables easy future system upgrades

- Quick switch-over times between different coatings maximizes machine uptime

- Substrate pre-cleaning and quality control equipment integrated into system for turnkey operation

- User-friendly operating system and easy maintenance

- Remote access for quick troubleshooting by AGC support team